- Tradeindia

- Cranes

- Crane Fittings

Crane Fittings

(31 products)Easy To Operate Hydra Crane Window Locks

Price Trend: 200.00 - 1000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeCrane Window Locks

ColorBlack

Equipment TypeLocks

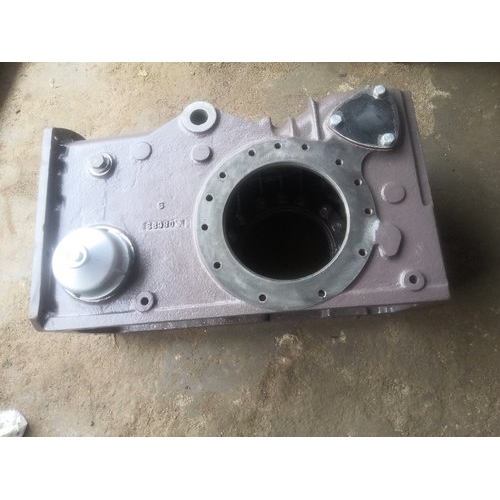

Escort Hydra Crane Differential Housing

Price: 12000 INR/Piece

MOQ10 , Piece/Pieces

Supply Ability500 Per Week

Delivery Time1 Week

Angle Cut Degree Cut Flat Bright Bars Application: Used In Cranes

Price Trend: 40.00 - 60.00 INR/Kilograms

MOQ10 tons Metric Ton

Sizeas per Your Requirement

Product TypeAngle Cut Degree Cut Flat Bright Bars used in Cranes

ApplicationUsed in Cranes

Aluminum Alloy Rail Cranes Application: Workshop

MOQ1 Unit/Units

UsageIndustrial

Product TypeAluminum Alloy Rail Cranes

ColorAny

Steel Industrial Long Life Crane Filter

FeatureHydraulic Crane, Truck Crane, Track Crane

Materialsteel

Crane TypeOther Cranes

Cranes and Hoist Retro Fitting

Payment TermsTelegraphic Transfer (T/T), Others

Delivery Time2 Week

Sample PolicyContact us for information regarding our sample policy

More details...

More details...

Top Rated Products

FAQs Related to Crane Fittings

Who are the top crane fittings manufacturers in India?

- Amratlal Chhaganlal

- Sweta Impex

- Panchal Crane Parts

- Aws Industries

- Hyko Technologies

- Veerkrupa Engineering

Which cities have the largest number of crane fittings suppliers?

- Pune

- Chennai

- Mumbai

- Delhi

- Faridabad

- Ludhiana

- Coimbatore

- Thane

- Rajkot

How many trusted sellers are available for crane fittings?

- AMRATLAL CHHAGANLAL

What is the minimum order quantity for crane fittings?

Do listed companies have registration & certifications?

- SWETA IMPEX

- HYKO TECHNOLOGIES

- JINDAL AUTO EXPORTS

What is the get latest price feature?

What types of payment methods are accepted by the crane fittings suppliers?

More details...

More details...

More details...

More details...

More details...

More details...

More details...

More details...

More details...

More details...

Latest from Crane Fittings

Hydra Crane Window Locks

By:

Panchal Crane Parts

Explore in hindi

क्रेन फिटिंग

Crane fittings are the most essential parts & components of any type of cranes known to us, as these play a vital role in the stability, efficiency and performance of the machine. Generally, cranes consist of several fittings such as hoists, conveyors, nuts and bolts of different size, boom, slewing unit, hoisting cable, girders etc.

The main raw material that is used across the globe for making these crane fittings is steel, which is an alloy of iron & small amount of carbon. For crane fittings that do not require high strength or that are used for making cranes with light to moderate lifting capacity, common form steel known as carbon steel is used. High strength low alloy (HSLA) steels are used for manufacturing crane fittings that are used for making cranes with heavy weight lifting capacity.

Crane Fittings : A Briefing

Following are the common fittings or parts of pedestal cranes :

Boom a This is the most essential part of a crane. Crane booms are the horizontal arms that lift and lower the load or other heavy materials. There are four main types of boom, which are Box section booms (which may be a single box or in A shape construction), Lattice booms, Knuckle booms and Telescopic booms.

Jib a These are extensions of the crane boom that extend out to give greater length to the boom and allow for high lifting capacity.

Rotex Gear a These are located under the cab or crane cabin and allow the cab to rotate or turn the boom by means of a hydraulic motor.

Operator's Cabin (Crane cabin) a These are attached to the top of the deck that have chair, electrical equipments and the crane's control panel. Operator controls the crane by using joysticks that control the motion of the boom and the foot pedals, which control the rotex gear pump pressure.

Detachable Counterweights a These are concrete slabs or blocks that are placed at the rear portion of the crane. Detachable counterweights help to prevent the crane from being unbalanced during the lifting operations.

Outriggers - These provide the stability and balance necessary to prevent the crane from leaning or overturning. An outrigger has three parts: the beam or leg, the pad or foot and sometimes the float.

Lifting Hook a These are used for grabbing and lifting loads. Different types of hook attachments are C hook, Gripping lifters, Vacuum lifters, Sheet lifters, Pallet lifters, Magnet lifters, Slings or strap hoist and Drum turners.

Wire Rope - The wire ropes used in cranes will either be a standing wire rope used mainly on lattice boom cranes, or running wire rope used as hoist line or boom hoist reeving.

In Overhead Cranes, Following Fittings are Used While Manufacturing or Assembling Applications :

Girders a These are the main traveling structure of the crane, which spans the width of the bay and travels in a direction parallel to the runway.

End Trucks a Located on either side of the bridge or girder that have wheels, on which entire crane moves.

Hoist a This is a unit that consists of motor drive, coupling, brakes, gearing, drums, ropes and road block designed to raise, hold and lower the load.

Trolley a This is a unit that carries hoisting mechanism, which travels on the bridge rails in a right angle direction to the crane runway.

Client Testimonials & Reviews

RohitSachdeva

EARTH EQUIPMENTS

We are associated with Tradeindia.com since 1 year. Its a good B2B Platform to do business and for promotion on Google as well. I would look forward to be in long term relationship with this company.

Paresh Kareliya

GANESH ENGINEERING CO.

We are very thankful to Infocom Network Ltd. and its services to promote our product through Tradeindia.com on Internet. We get good support from their CRM and getting good Inquiries for Domestic as well internationally. We came to know of several portals but we choose Tradeindia.com for its services and different features we had been member since last 2 years and already subscribe for 2 more years in advance. from our Point of view we think Tradeindia.com is one of the best portals which we came to know from many years of experience of our business. We recommend Tradeindia.com as one of the best portal in online and off-line promotion for business activities. We wish Infocom Team and Specially their CRM Support Team for a great success in coming years and also wish that they will continue doing good work for long period.

Crane Fittings Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Amratlal Chhaganlal Mumbai, India | 16 Years |

Sweta Impex Mumbai, India | 12 Years |

Panchal Crane Parts New Delhi, India | 10 Years |

Aws Industries Faridabad, India | 5 Years |

Hyko Technologies Thane, India | 5 Years |

Veerkrupa Engineering Ahmedabad, India | 3 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories